Immersion

1. Definition

Immersion cooling is a method of heat removal from a working device by immersing it in a specialized container with a dielectric fluid (immersion liquid).

2. Two kinds of immersion cooling

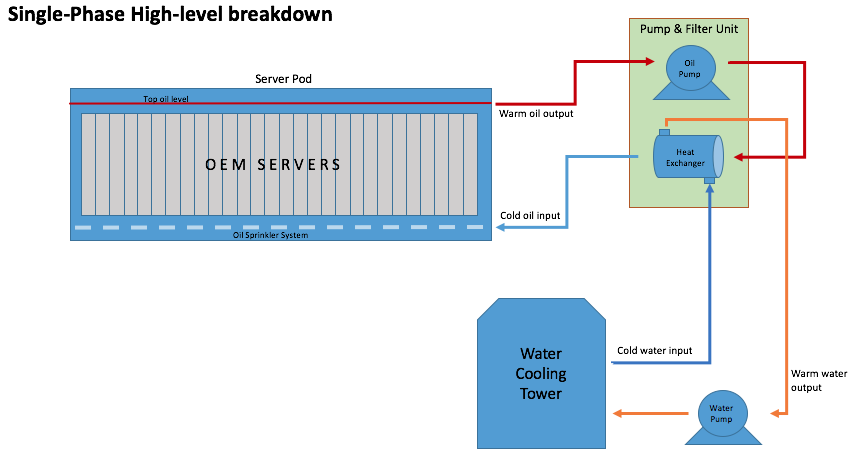

1) Single-phase immersion cooling

In this system, hot fluid is pumped out and returned after being cooled, which makes plumbing more complex than two-phase cooling and is rather inefficient.

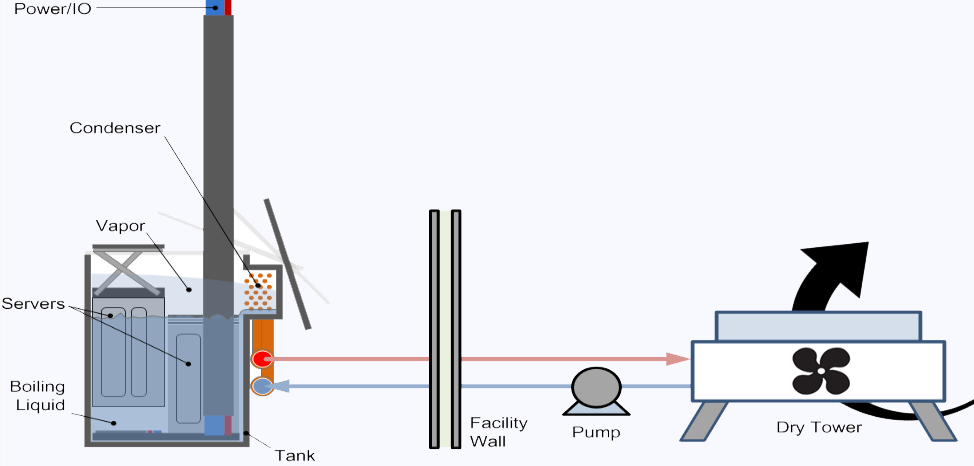

2) Two-phase immersion cooling

The figure depicts a two-phase immersion cooling system. In this system, the fluid boils on the chips and the phase change provides the majority of the cooling. The reason why it is called 2 phase is that the heat is transferred by evaporation and condensation . Unlike single phase cooling, the fluid is not water but a dielectric fluid made by 3M, called Novec and Fluorinert Fluids, which keeps equipment dry when removed. This fluid boils at 56℃ and the vapor will then condense on the coil, followed by raining back to the fluid bath. These systems are more complex than single-phase systems but offer higher efficiencies, scalability, and lower maintenance . As a result, its benefits far outweigh the added complexity.

Source: https://www.e3nv.com/immersion-cooling-overview

https://www.youtube.com/watch?v=SP9yXBWPK2Q

https://www.youtube.com/watch?v=FTq0Q7O0u7E

Advantages:

- Higher upfront cost but a shorter payback period and better ROI

Figure 1 Payback periods of different cooling methods

Cooling method | Cost | Revenue | Expense | Payback (Months) |

Air | 600,000 | 100,000 | 60,000 | 15 |

Water | 1,400,000 | 120,000 | 60,000 | 23.3 |

Single phase immersion | 1,000,000 | 120,000 | 45,000 | 13.3 |

Two phase immersion | 1,100,000 | 140,000 | 45,000 | 11.6 |

Sources: https://www.e3nv.com/

- Keeping the temperature of the machine low and stable leads to longer lifespan of the devices The thermal conductivity of the liquid is 25 times higher than in case of air cooling , which significantly increases the degree of thermal stability within the installation.

Eg. a processor’s temperature at full power usually reaches 85 ºC, at an ambient temperature of 32 ° C. If the processor is immersed into the liquid, its average temperature will be about 65 ºC under the same conditions

Such high degree of thermal stability and heat conductivity allows to exceed the maximum power and overclock the equipment to achieve higher Hashrate, which will increase its productivity by 20–40% , depending on the tasks assigned.

- No dust accumulation risk

- High density of the equipment placement

A standard 10-foot ISO-container can contain 2.5 times more ASICs and 6 times more GPUs than in case of using air-conditioning.

- Save lots of space which can be used for the equipment placement

Without the need to install extra ventilation and professional cooling system, the spare space can be used to install more machines, resulting in a higher density (approximate 16x increased density).

- Significantly reduces electricity consumption from conditioning, which saves over 20% of previous expenditures

- Eliminating fan and power supply replacement costs

- Decrease staff up to 75%

Disadvantages

- Not ideal at small scales

- Complex and expensive constructions

- Tanks must be stainless

- Fluids leak easily so quality control must be tightly adhered to

- Additionalcost to hire experience and professional engineers to handle the immersion system

Source: https://www.e3nv.com/immersion-comparison

Air cooling

Advantages

- Extremely well understood and quantified

- Equipment is easy to service at large-scale

- No plumbing or fluid used

- Current OEM systems are designed for air cooling

Disadvantages

-

Large scale cooling result in

extraordinary high electricity bills

- Antminer S9 with a power consumption of about 1350 watts require 4,000 cubic meters of air per hour. As you can see, in order to prevent overheating, you need extra conditioning, which implies extra expenditures on cooling facility, ventilation, professional conditioners, maintenance.

- Dust accumulates static electricity, which can lead to equipment failure in the long term.

-

Noise control

- 1 ASIC generates the noise of 75dB, which is quite acceptable, but if there are 10, 100 or 1000 ASICs, it will cause huge discomfort, especially for a person who looks after the farm constantly, almost 24\7.

- Lack of thermal stability and uneven equipment heats from different parts result in shorter lifespan

Source:

https://medium.com/@bixbit.official/immersion-cooling-or-how-to-stop-wasting-money-on-air-e851938d80df ; https://www.e3nv.com/immersion-comparison ; https://medium.com/@bixbit.official/

Takeaways

- Immersioncooling requires higher upfront cost but a shorter payback period and better ROI than air

- Immersion cooling keeps the temperature of the machine low and stable in order to achieve a longer lifespan of the devices and a higher performance when overclocked.

- Immersion cooling saves up to 40% of the maintenance and electricity costs because it has no dust accumulation, and requires fewer cooling expenditures.

- Immersion cooling generates significantly less noise, which could be a main concern in regions that have specific requirementsto noise control.

- Immersion cooling is more complex to construct and requires professional equipment and staff for operation.

- Immersion cooling is not suitable for small scale facilities.